Bio-mimicking coating for improved infection control

LipoCoat bio-inspired coating technology, aims at medical device comfort, safety and performance improvement. The coatings mimic the natural cell membrane, retaining many properties observed in natural cell membranes and offers surface property improvements in anti-fouling, wetting and lubricity for improved comfort and safety for patients.

LipoCoat's technology offers the improvement of medical devices. As a coating specialist LipoCoat requires innovative companies who are willing to apply our technology to their medical devices where we help our partners to collect the data necessary for the market approval and registration. In return, we need the know-how of our partners to understand and define the future market and product requirements to tune our coating technology to outperform currently available products.

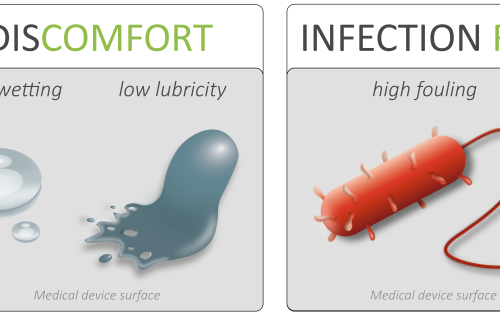

In many fields there is a mismatch between surface chemistry and the intended application. Poor surface properties can lead to discomfort or contamination which in turn can lead to bigger problems. A global challenge in healthcare is complications that arise due to complications in medical devices. Especially contamination of devices such as catheters are one of the leading causes of Healthcare Associated Infections (HAIs).

It has been estimated that around 6% of HAI cases result in death. According to a GE whitepaper, every year in the US alone, HAIs affect about 1.7 million people at a cost of more than $35 billion. HAIs are responsible for prolonging hospital stays by approximately 16 days and causing nearly 100,000 deaths annually. The situation is similar in the European Union, where yearly over 4 million patients acquire a HAI. These infections are estimated to contribute to roughly 110,000 deaths, along with significant cost to health systems. The direct costs were estimated by the World Health Organization to total at least EUR 7 Billion, every year.

LipoCoat© coatings are aimed at reducing HAI cases and improving medical device comfort and performance in a drug-less, no-active fashion using a bio-inspired mild solution. We work on proprietary solutions to tweak surface properties to make the outcomes more predictable. These solutions are bio-mimetic nano-coatings that offer control over wetting, lubricity, and fouling. In turn this improves comfort, safety, and performance of the substrate.

In nature, the cell membrane, more specifically the phospholipid bilayer, serves as a universal interface between distinct chemical environments. These membranes shield the inside of the cell by regulating the passage of molecules and proteins.

LipoCoat is a bio-inspired coating technology of 5 nanometers thick. By mimicking the natural cell membrane consisting of a phospholipid bilayer, biocompatible and high-performance medical device coatings can be prepared. LipoCoat has developed multiple proprietary coatings to exploit these properties and have assembled a toolbox of various base molecules and gathered the know-how to tailor coating composition and architecture to meet application needs. As such, LipoCoat is a membrane-mimetic coating with regenerative properties, anti-fouling, wetting and lubricous properties that are introduced by chemical control of the interface composition.

The coating is non-covalently attached to the substrate. The coating does not require a curing step But may require a surface pre-treatment step before the coating can be applied. This can be achieved with oxygen plasma or chemical priming. Subsequently the coating is easily applied by means of ‘dip-coating’; the self-assembly property ensures an evenly spread, 5nm thin layer.

Due to the changing demography in the industrialized countries with a growing number of elderies, there will be also a higher burden on the healthcare sector due to a higher demand on age related medical treatments often combined with surgeries or hospital stays. As it is known than in average with the age of 65 the weakening immune system has a noticeable impact on health, hospital stays and surgieres present an imminent risk of those who are already in a weakend condition due to a high infection risk, in worst case an infection of multiresistant bacteria, a threat where almost no antibiotics can't coontribute anymore to the health of such patients. And that's where LipoCoat's vision and mission starts. Instead of developing new methods of killing bacteria, LipoCoat's technology uses a fully proven system by nature itself, the lipid cell membrane, to be applied on medical devices to prevent the attachement of any type of pathogens and therefore preventing infections and keeping patients safe, resulting in healthier patients and a reduced burden on the healthcare system.

Since LipoCoat offers its bio-mimicking coating technology but not a coating service itself, LipoCoat's target audience are medical device manufacturers and distributers (OEM) willing to apply the coating on their final medical device which eventuelly will be used for patients in need of such unique medical device surface improvements.

Every year combined in the USA and Europe, 140.000 people die due to healthcare-associated infections (HAI) and more than additional 6 million patients are affected, which result in a € 35 billion cost burden for the healthcare systems. One of the leading sources of such infections are catheter related bloodstream infections (50 % of HAIs), causing in € 25-40k costs per case.

LipoCoat's coating technology will significantly reduce the risk of HAI by strongly reducing the risks of infections and therefore lowering the burden on the healthcare system.

LipoCoat offers it's coating solution itself to a low, near production costs price to not artificially increase the pricing of the final product and takes a certain percentage (5-10 % depending on the device) of Royalty to participate on the success of the novel upgrated medical device being used by the patients.

Depending on the product class e.g. Catheters or contact lenses, there is only a limited number of competitor coating technologies while non of those have the same approach as the technology of LipoCoat. Many companies make use of chemical components which might lead to the death of pathogens, however it's also known that many of the used components can also lead to other adverse effects such as allergical reactions or just have a highly limited functionality in terms of infection reduction.

LipoCoat makes use of only plant and plant-derived lipids. Those lipids are partially used already for decades in the food and cosmetic industry without any adverse effects. Since LipoCoat's technology provenly reduces the attachment of pathogens, improves the comfort with the overall result of keeping patients healthy and reducing the costs for treatments in the healthcare system.

LipoCoat's coating technology is fully bio-compatible and makes only use of plant-based components. Different to competitor products, LipoCoat coatings fullfill multipurpose functions by reducing the attachement of bacteria and proteins, increases the wettability and lubricity, reducing the foreign body responds (according to preliminary data) which will lead all together to an improved comfort and safety for the patients.

LipoCoat is owner of a variety of patents, protecting the coating formulation and the processes itself be used for different regions on the globe such as Europe, USA, South America, China, Hong Kong and Japan.

LipoCoat will become of the global leading companies to develope biomimicking coatings for a variety of different medical and non-medical applications for short-time and long-time usage. We will use our expertise in chemistry and microbiology to be able to adapt our technology to new application use-cases which are also not just directly connected to coatings but also other treatments such as eye sprays and care solutions. Additional we can offer research services to analyse and evaluate surfaces to give potential future customers an idea of their current quality of their product surfaces. Since our coating production can be easily upscaled and in the future also partially automated, we most probably won't require a number of employees above 30.

Different formulations of LipoCoat have been tested already in vitro regarding different parameters by external parties such as hemocompatibility and cytotoxicity, contact angle, lubricity, bacteria and cell attachment.

Additionally, several formulations have been tested as well in vivo during either animal or human studies regarding comfort and performance.

LipoCoat performed with its partners already several clinical studies in different projects to proof the benefits of our coating technology. In parallel we are now in the process to prepare additional animal studies for a variety of different types of temporary and permanent implants (CVC, Breast, Teeth, Contact lenses). The commissioned clinical studies have been performed and analized by leading external CROs (clinical research organisations).

In vitro results:

- improved contact angle/wettability

- strongly reduced attachment of bacteria

- strongly reduced attachment of proteins

- improved lubricity

- non cytotoxic

- hemocompatible

- reduced activation of immune system

In vivo results:

- reduced foreign body responds

- higher comfort compared to competitor products or non-coated

- reduced inflammatory reaction comapred to non-coated devices

LipoCoat is an expert for developing bio-mimicking coatings which eventually will be applied on a varienty of different types of medical devices. Therefore, we require partners including medical device manufactuers and distributeres (OEM) who are willing to explore the opportunity to implement our technology in their final product as the legal manufacturer of this upgraded medical devices making use of LipoCoat's unique coating technology.

LipoCoat works together with many national and international companies. In the end of 2022 we announced our collaboration agreement with CEMMA Medical, which is one of the leading medical devices manufacturers in China and South East Asia, as well as in the beginning of 2023 with Heraeus Medevio which is of the leading medical device OEMer in the USA and Europe.

2015: Winner of Jury award Dragon’s Den NNNL

2015: Winner of Audience award Dragon’s Den NNNL

2015: Winner pitch Holland-Innovative

2015: Winner NanoLabNL Voucher

2015: Winner Audience Award NanoCity

2015: Finalist Young Technology Award

2016: Winner NanoNextNL valorisation grant

2016: Winner Business pitch Health Afslag Twente

2016: Finalist TOM

2016: Awarded Red Medtech Ventures

2016: Start-up of the Year award Minac

2016: MIT-grant RVO

2017: Special award business delegation Tokyo

2017: Pre-seed investment from LLX2 Investments

2017: SME-instrument Horizon 2020 grant

2017: NWO Take-Off 2 Phase 2

2018: High Tech Lease Fund Grant

2019: EU Seal of Excellence

2019: Top 10 Academic startups Netherlands

2019: Top 30 Global startups – GIST Catalyst

2019: European Biotech Startup of the Year

2020: Announced as 'Best Medical Device Coatings Company of 2020'

2021: listed in the KVK Innovation Top 100

2022: Winner of Extreme Tech Challenge Netherlands & Belgium

Currently LipoCoat's biomimicking technology relies on the passive approach of preventing the attachement of pathogens. In the future we might add also bio-mimicking components which lead to a more active approach of killing pathogens and to use our coating as well as a carrier to implement and release over time certain drugs e.g. to promote the host tissue integration or other local required administrations of certain drugs such as in cancer treatment.

Right now LipoCoat has already many collaborations on the academic and industrial level all over the world, such as USA, Netherlands, Germany, South Korea, Taiwan, Japan, Belgium, New Zealand, Autralia, Romania, Italy, Spain and France.

Since LipoCoat's technology is applicable to medical devices used all over the globe, LipoCoat is aiming for nothing less to be one of the leading companies for coatings world wide, being used on a variaty of medical devices such as catheters, contact lenses and in the future also for permanent implants.